Tel: +86-0755-29816539/81792164

Fax: +86-0755-29816539

E-mail:q@alirubber.com

Address:1F 5 Building,Huafengzhenbao Industrial Park,Beihuan Road.Shiyan Town.Shenzhen China.

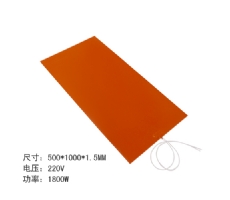

Silicone rubber heater

Silicone Rubber Heater No Length Limitation

sort:XD-H-169This product has been viewed

Sort:XD-H-169

Welcome to call us

alirubber.com@163.com

Silicone Rubber Heater For Gas Container/Oil Drum/Water Tank/3D Printer

Features:

1) Heating fast and long time using

2) Flexible and customization, thinness and lightness

3) Waterproof and non-toxic, odourless

4) Easy to use and operate

5) High thermal conversion efficiency

6) Good insulation property

7) Can prefect contact with the heated

8) Can be stick to the heated (have adhesive)

Dual Voltage, Zoning and Three Phase

Due to the flexibility in circuit design of silicone rubber heaters, multiple heating circuits can be designed to accommodate dual voltage and multiple zones. On dual voltage heaters, three leads, including a common in a different color, are provided for wiring the heater in series for the higher voltage and parallel for the lower voltage. 120/240 Vac or 240/480 Vac can be achieved. Multiple circuit areas can be zoned to achieve different heating effects. Three-phase circuits also can be designed for high current applications.

a) Etched Foil Silicone Rubber Heaters

The etched element provides superior heat transfer and exceptionally uniform heat output, which results in a faster warm-up cycle and longer life. The heaters operate in ambient temperatures from -80°F to 500°F.

b)Wire Wound Silicone Rubber Heaters

The excellent dielectric properties of silicone rubber and the strength of fiberglass combine to produce a unique heater. First, fine nickel-chromium alloy wire is spiraled onto a center core of fiberglass twine, producing a strong, flexible heating element. Electronically-controlled precision winding equipment ensures consistency.

Circuits are then hand-wound on permanent tooling providing repeatability of resistance and pattern. Parallel circuits are utilized where possible, permitting continued operation should a single circuit be damaged.

When the heating element is positioned, a second layer of silicone rubber is laid over the wire. The layers are then vulcanized to permanently position the circuits.

Using these versatile and flexible heaters, the ability to apply heat exactly where required is limited only by imagination — and a maximum continuous operating temperature of about 200°C

![]()

![]()

![]()

Inquiry or leave a message please fill in the following feedback form, we received after the form in 1-3 working days give you an answer, please be sure to fill in your true contact way!